CRGO Transformer Lamination

CRGO Transformer Lamination core

Transformer core lamination for Power & Distribution transformers is manufactured from various grades of Cold Rolled Grain Oriented (CRGO) steel. Lamination in various shapes & sizes are slit and cut to required accurate geometrical shapes with 90° & 45° cutting systems. The manufacturing of Cold Rolled Grain Oriented CRGO Quality Lamination involves a high degree precision engineering.

Transformer lamination can be of various sizes for single or three-phase transformers, made with overlap joints or step lap joints (Cross/Longitudinal). They are cut, punched and V-notched in order to fit in a particular transformer. Cutting, Punching and Notching of different shapes of sheets are possible in width up to 1000 mm and length up to 5500 mm.

Slitting process is the origin where quality standard starts, and subsequently it is maintained by the different types of cutting process. Quality of the material is always on top priority at Evergreen and thus we stress more on slitting process for better quality in every single process.

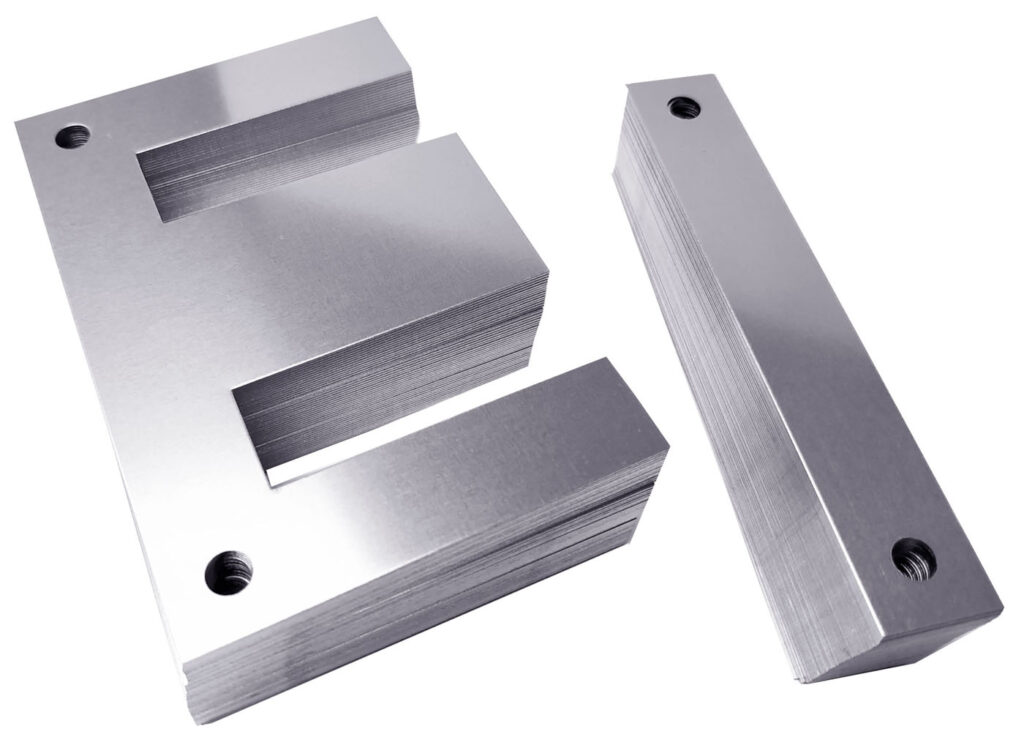

In addition to the cutting of the CRGO lamination, we offer built core, assembled core (Overlap/Steplap joints).

Lamination Quality Check

Lamination quality control checks are carried out frequently right through the starting of manufacturing process on machine to the dispatch. All the records are maintained separately for each drawing so the tracking of particular job can easily be available on our finger tips. As a final step of process, delivery inspector conducts the required inspections of CRGO lamination and releases it for the dispatch

Step-lap CRGO Transformer Lamination Core

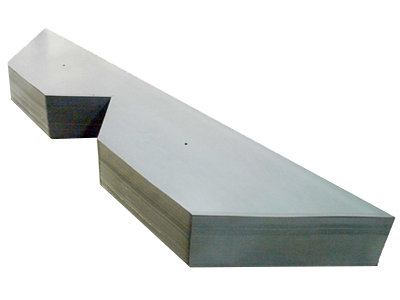

The Step-lap CRGO Transformer Laminations design leads to low no-load losses and a low noise level, lateral step-lap enables a favourable assembly for the upper yoke. Every type of CRGO Transformer Cores can be produced in a form of Step lap, over lap, 45° cut, with hole or without hole from every required quality electrical steel up to 800 mm width. Evergreen uses the newest, computerized version of Cut to Length Machines in order to produce Step-Lap CRGO Transformer Laminations Cores.

Cutting quality is constantly controlled with latest technology

Electrical Testing

All cores, unless otherwise state, are individually tested to the standard guarantee specifications. Special test conditions, when required, can be applied and guaranteed to suit customers’ individual requirements.

It is well known that handling and processing of Grain Oriented Electrical Steel (c.r.g.o.) can create undesirable stresses within the metal internal structure and at the cut edge. Therefore cutting quality is constantly controlled with latest technology equipments.

Carbide slitting lines are used in order to achieve a minimum formation of burr in the cutting edge if coils.